Department of Chemical Engineering: Laboratories

The purpose of this lab is to introduce the basics of mass transfer operations within and during inter-phase transfers, through experimentation. It aims to understand the practices carried out in chemical process industries and provide a hands-on training to the undergraduate students on the equipments. This laboratory having various notable sophisticated equipments, including Absorption In Packed Bed Column , Wetted Wall Column, Cooling Tower, Fluidized Bed Dryer, Solid Dissolution Apparatus, Single Effect Evaporator, Solid In Air Diffusion Apparatus.

Mass transfer operations are primarily the responsibility of chemical engineers. The purpose of this laboratory is to introduce the fundamental concepts, principles to various separation processes such as distillation, liquid- liquid extraction, solid liquid extraction, adsorption and ion exchange. The laboratory equipped with equipments such as Bubble Cap Distillation Column, Liquid- Liquid Extraction Column, Batch Crystallizer, Ion Exchanger, Spray Column, HTU, HETP & NTU Column, Solid Liquid Extraction, Adsorption Column, Vapor Liquid Equilibrium setup.

Since the majority of chemical-processing operations are conducted either partly or totally in the fluid phase, the study of fluid dynamics is important. The lab helps the students to understand the behavior of fluid under various forces and at different atmospheric conditions, and to select the proper fluid for various applications. The lab involves the various experiments such as verification Bernoulli's theorem, flow rate measurements, investigation of fluid flow laminar or turbulent etc. For that various equipments such as Venturi Meter, Orifice meter , Nozzle Meter etc. are available.

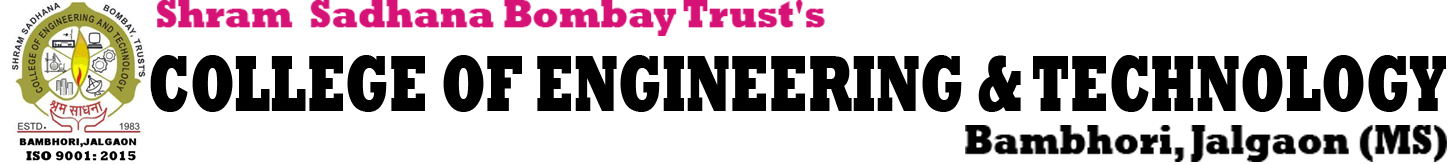

Mechanical operations frequently carried out in chemical process industries involve size reduction of solid, separation of solids, purification of solids and much more. This laboratory is intended to fulfill the need for comprehensive laboratory course in particle and fluid-particle processing. Plate & Frame Filter Press, Vertical Pressure Leaf Filter, Ribbon Blender, Sigma Kneader Mixer, Vibrating Shifter , Mini Pulverizer, Sieve Shaker, Cyclone Separator, Fluidized Bed apparatus, Ball Mill, Jaw Crusher and Sieves of various sizes, are the notable equipments available for students for understanding and hands on training.

Instrumentation Laboratory involves the use or application of instruments for observation, measurement or control of quantities such as temperature, concentration, pH, conductance etc., which are frequently encountered during transformation of reactants to products. The laboratory provides hand-on training on various instruments to chemical engineering undergraduates. The laboratory is equipped with instruments namely Digital pH Meter, Thermocouple, Bimetallic Thermometer, Digital Conductivity Meter, Colorimeter, Abbe Refractometer etc.

Process control is the study and application of automatic control in the field of chemical engineering. The primary objective of process control is to maintain a process at the desired operating conditions, safely and efficiently, while satisfying environmental and product quality requirements. Process Control laboratory provides a “hands – on” experience and plays an important role for understanding of theoretical concepts. Pneumatic Control System, Control Valve Characteristics, Dynamic Response of Control Valve & Rota meter, Dynamics of Single Tank System, Dynamics of Two Tank Non-Interacting System, Dynamics of Two Tank Interacting System, On off Temperature Controller, Temperature Control Trainer, Flow Control Trainer, Pressure Control Trainer are the notable equipments of this laboratory.

Project Laboratory provides chemical engineering students the opportunity to observe, analyze and apply their engineering knowledge and training to the operation of equipment and processes commonly found in many chemical industries, through their minor and major project research work at the undergraduate levels. The intention behind to set-up this well equipped laboratory is to facilitate the students with modern laboratory instruments for their project research work, which includes synthesis and designing projects. Penske Marten Flash Point Apparatus, Orsat Apparatus, Digital Melting Point Apparatus, Cloud Point And Pour Point Apparatus, Digital Electronic Balance, Penetrometer Apparatus, Drop Point Grease Apparatus, Photo catalytic Reactor, C.O.D. Reflux Apparatus, Evaporator Set Up, Micro Kjeldahl’s Distillation Assembly, Hydro Pulper, Paper Shredding Machine, Film wise and Drop Wise Condensation, Dimple Tube Heat Exchanger are the listed equipments of project lab.

The computer lab is established to support the students in their educational tenure by providing computers with latest configurations. Computers are equipped with internet access, scanner and printer and with power backup. Lab computers and chemical engineering related software’s available in the laboratory, allow the students to complete course assignments and also help them in learning new programs and languages, which are important in their post education professional career.

Various phenomena are considered as important in the field of chemical reaction engineering, such as fluid dynamics, mass and heat transfer, and reaction kinetics. The primary purpose of chemical reaction engineering laboratory is to apply the theoretical knowledge, during hands-on training sessions on various modern equipments for optimization of chemical reactors, feed composition and operating conditions. The notable equipments available to students includes Rotating Basket Reactor, Catalytic Packed Bed Reactor, Continuous Stirred Tank Reactor, Plug Flow Reactor (Straight Tube Type), Plug Flow Reactor (Coil Type), Cascade Continuous Stirred Tank Reactor, Packed Bed Reactor, Annular Reactor.

The main role of chemical engineers is to design and troubleshoot processes for the production of chemicals. This lab provides supports to the students for understanding standard operating procedures during synthesis of single stage chemical preparations, analysis of chemical compounds, quantitative and qualitative analysis, experimental investigations of reaction rates. The equipment facilities available in the laboratory includes High Temperature Oil Bath, Laboratory Oven, Viscometric Bath, Vacuum Pump, Muffle Furnace, IR Lamp, Magnetic Stirrer with Hot Plate, Heating Mantle, Electronic Balance, Water Bath, Centrifuge, Refrigerator, etc.

Research allows one to pursue his interests, to learn something new, to synthesize new products, to provide one’s views on the topic, through experimentation with chemicals on sophisticated instruments. This lab is intended to provide modern state of the art technical support with computer facilities to the aspirants undergoing PhD in chemical engineering and allied disciplines. The lab is well equipped with modern instrumental facilities such as FTIR Spectrophotometer, Cone Penetrometer, Soxhlet Extractor Unit, Melting Point Apparatus, Digital Electronic Balance, Reflectance Meter (Photo Volt Type), Say bolt & Redwood Viscometer. These modern equipments and peaceful environment of the laboratory accelerates the research work of a devoted researcher.